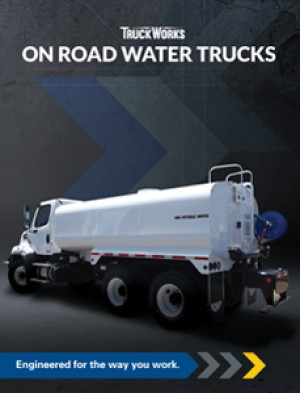

On-Road Water Trucks

You can take control of your next water truck purchase by being a part of the process from start to finish. We offer an array of design configurations for you to choose from and will work with you to find out exactly what you need, to your exact specifications. With industry leading standards, our on-road water trucks are not only some of the most aesthetically pleasing trucks, but also the most durable. Starting from practically any chassis and ending with a truck worthy of any on-road application, every step of the truck building process is designed with you in mind. You can choose from 1,000 to 7,000 gallon tanks, a series of spray nozzles, pump systems, hoses and more, to help make a truck specialized to your business operations. Whether the reason is dust control, compaction, or mine hydration, we can engineer and equip your truck with the proper mechanics to prepare it for more than one application. By designing a truck based on its use rather than just the truck type, we eliminate the possibility of providing you with the typical cookie cutter water truck.

You buy a water truck engineered to deliver powerful performance and designed specifically for you, but like all water trucks after years of use, they could begin to corrode. The development of rust and corrosion can lead to costly repairs and an unsafe reduction in metal thickness. As experts in the tanker manufacturing industry, we offer a cost-effective solution that can protect your water truck from corrosion and dramatically increase the longevity of your truck. Our hot-dip galvanization option forms a fully protective coating to ensure your tank body is corrosion resistant. Dipped in molten zinc to ensure durability and strength, your tank body will be protected from corrosion and prepared to last for years to come.

For you, our capabilities go far beyond your average water truck manufacturer. We have a unique process behind building the best on-road water trucks in the industry. Your water truck will be designed using SolidWorks, stress analysis and weight distribution simulation so that it’s ready to be put to work as soon as you get it. We combine thorough testing with advanced quality control systems to keep you from experiencing common on-road water truck challenges, such as pump or valve failures that can result in jobsite closures due to inadequate dust control. It’s imperative to us that your water truck is equipped using more than just the standard parts to get the job done, but is engineered to get the job done in the most efficient way possible.

From flushing curbs and gutters in the city to providing fresh water to rural areas, we can install task-specific components that will help you do your job better. Our on-road water trucks comes in a variety of specification levels to meet your requirements:

Rental Grade – Our rental grade tank provides high quality construction with a reduced feature set to meet an entry-level price point. This tank is constructed using 3/16” A-36 mild steel with baffle spacing not exceeding 60”.

Commercial Grade – Our commercial grade tank is designed and built to meet the requirements of highway and construction market applications. This tank design has greater structural composition with a ¼” tank bottom plate, U-shaped subframes with 4 points of contact, and is 100% welded for a solid finish. This tank also features a single bend long “longitudinal” baffle extending the full length of the tank.

Severe Duty Grade – Our severe duty grade tank is designed and built to meet the demanding requirements of mine applications, rough road and uneven working conditions. This tank’s design is superior to our commercial grade in that it features an inset break design, offset heads, and baffles that do not exceed 48” for the greatest structural stability. Additionally, baffles are 100% welded and the tank features dual long baffles that extend the full length of the tank as well as a 5/16” bottom plate for the greatest durability.

Galvanized – Our galvanized tank is suitable for similar applications as our severe duty tank, but adds superior rust and corrosion protection that significantly extends the life of the tank. This tank design features baffle spacing not exceeding 48”, 100% welded, and dual long baffles. The fully-constructed tank is then dipped in molten zinc to provide a corrosion resistant product inside and out.